|

|

SOME PROUD PARENTS SHOW OFF home movies of their children at birthday parties. Other people like to share videos of yarn-entranced kittens or Frisbee-catching dogs. Robert Full dazzles visitors with films of geckos. On a recent day in his office, surrounded by dangerously overstuffed bookcases and a menagerie of plastic insect toys, he calls up a French TV news clip on his computer. A tiny green and yellow-spotted gecko fills the screen, hanging precariously by a single toe from a line of string. With a broad smile, steady eyes and the seasoned delivery of a motivational speaker, Full leans forward and speaks. “What’s amazing” — he pauses dramatically — “is that he is totally not stressed out. He’s just breathing normally, like nothing is wrong.” Despite any intuitive notions to the contrary, it’s true. The gecko’s creamy throat expands and contracts at an average pace for a five-inch-long lizard. His black marble eyes remain open and unmoving. Full, on the other hand, sits back and lets out a deep, rolling belly laugh, his point made. For geckos have just about the strongest grip in the animal kingdom, and he knows how. About 10 years ago Full, a professor of integrative biology at the University of California, Berkeley, first took the time to appreciate the amazing feat of biological engineering that lets geckos speed up walls, whisk through water, and even dangle dispassionately by their big fat toes. In 2002, Full and his collaborators, including former graduate student Kellar Autumn and UC Berkeley engineer Ron Fearing, showed that a weak, ubiquitous molecular force binds the billions of teeny hairs on a gecko’s foot to all kinds of surfaces. “But,” says Full, “a pathetically weak force multiplied by a billion is no longer pathetically weak.” Full is chuckling again, his broad mouth stretched wide under a thick, curling mustache. He looks every bit the scientific circus master behind this three-ringed research program that intertwines biology, physics and engineering. Today the group is developing a reusable adhesive based on the blueprint of a gecko’s foot. They’ve already made patches of synthetic hairs that are about a tenth as strong as real ones. Full and Fearing want to use their synthetic gecko hairs for biologically inspired robotics, a field where both researchers are actively involved. Nearly completed robots, designed to climb and explore with ultimate animal efficiency, are waiting in the scientists’ labs in various states of dismemberment. The robots’ empty toe-pads are just itching for the adhesives to reach their necessary strength and durability. Private industry is practically knocking down the researchers’ doors to get dibs on the technology, even in its early stages of development. Full won’t name any particular corporate interests, so as not to compromise pending deals. “Just use your imagination,” he says with a wink. There are obvious choices, though: DuPont, 3M (the makers of Scotch tape) and Nike, to name a few. Johnson and Johnson has already expressed interest in gecko Band-Aids. The possibilities, Full says, are limitless: “Look around you. Everything has parts that are stuck to each other. Almost every product requires something to be attached to something else. And you can make gecko-like adhesives out of the stuff of your choice — to be degradable or not. Or even metal. That’s why it’s going to be so big.” Judging by the success of some other biologically inspired products, Full might be right. Just think of Velcro. In the early 1940s, Swiss inventor George de Mestral took a close look at the cockleburs that fastened to his pants and his dog’s coat during country walks. With some careful investigation under a microscope, he came up with the idea for Velcro based on the stiff hooks of the burr and the soft, threaded loops of his trousers. Sixty years later, the design process is pretty much the same. Pair an insightful observation with detailed study, and who knows what can happen? From synthetic spider silk to fake bones, super-fast shark-like swim suits to octopus-inspired underwater robotic eyes, the product potential is as vast as the natural world itself.

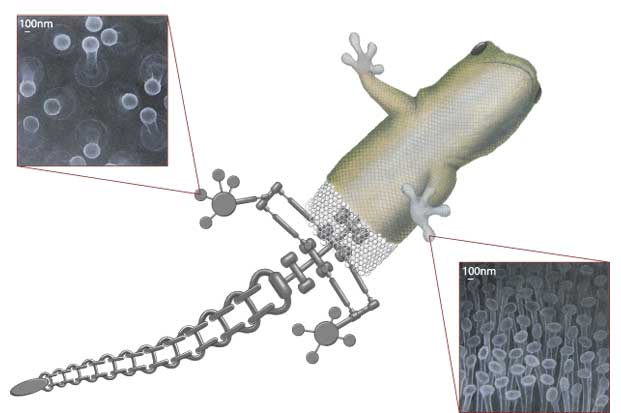

GECKOS HAVE SOME OF THE STRANGEST looking feet around. Ignore for a moment that they come in a rainbow of colors — pink, purple, green and yellow — and instead concentrate on their disproportionate size and wacky treads. Some species have feet textured like an orderly striped rug, while others resemble an unwieldy cabbage, with folds and flaps and lines of hairs twirling in all directions. It was these floppy feet that inspired Autumn in the mid-1990s, when he was working on his doctoral thesis, to test if geckos were equally sloppy runners. But they weren’t. “The cost of locomotion is actually a fifth of what was predicted for animals their size. So they are actually really economical,” says Full. And while efficient locomotion is a boon for any creature, geckos probably need it more than most. The creatures are nocturnal, branching off from their daytime-loving relatives to take advantage of the relatively predator-free environment of the night — just like moths took an evening-inspired evolutionary turn away from butterflies. But geckos, like other lizards, are cold-blooded. Without the warming rays of the afternoon sun, it’s hard to get those muscles in gear. Evening efficiency, according to Autumn, is therefore a must. But the gecko’s supreme skill is its ability to scale vertical surfaces. Using a force platform fixed to a wall, sort of like a scale mounted sideways, Autumn measured the push and pull of a Tokay gecko’s foot as it sped past. What he found was stunning — hardly a drop of energy was lost to friction. Somehow, these deft little creatures can place their feet and pick them up again with seeming mechanical perfection, says Full. Full is well acquainted with the elegance of animal movement. He has studied locomotion for a couple of decades now, in creatures ranging from centipedes to salamanders, taking their pearls of wisdom and applying it to robotics. He and his collaborators have designed robots based on the stable, streamlined crawling of crabs, cockroaches and even snakes. Pixar Animation Studios asked him to be a consultant for their 1998 film A Bug’s Life to make sure all their characters moved with a realistic gait. But his favorite movies are the ones he has filmed of geckos. Full loads up another video. This time two geckos are running side-by-side, shown in a split black and white screen. They move in perfect unison, undulating their robust, spotted bodies and thick, pointed tails at an alarming pace. But despite the apparent similarities, these lizards are doing something remarkably different. “One of them running up a wall and one of them is running on the level,” he says. “We did the motion analysis. The forces have to be different because of the physics, but the motion is exactly the same.” It’s hard to imagine any other creature achieving similar unity in vertical and level locomotion; think of a person walking casually up a wall, without the slightest apparent pull from gravity. “So we said, Okay, we’ve got to look at these bizarre toes and figure out what’s going on,” Full recalls. “Other people had looked at the structures and [made] hypotheses about them, but nobody ever tested them.” Besides their various colors and outlandish shapes, gecko feet have a uniquely elaborate structure. The toes’ flexible backing holds millions of tiny hairs called setae, all in ordered rows. In most gecko species, the tips of these hairs have split ends — even tinier projections called spatulae — that finish with a smooth disc-shaped top, giving them the overall appearance of a flower. Just like human hairs, they are made of the protein keratin. But measuring a mere 200 nanometers at the very tips, they are hundreds of times smaller, and visible only under a powerful electron microscope. Depending on a gecko’s weight, which can range from a few grams to a few hundred grams, each lizard has around a million setae and up to a billion spatulae tips. In 1998, Full set his team to the daunting task of measuring the grasping force of a single gecko hair. The technology to measure forces or objects so small didn’t even exist. But in a stroke of luck, he met Stanford University engineer Tom Kenny at a conference. Kenny was showing off his research on micromechanical cantilevers that could measure unthinkably miniscule forces. The only problem was that Kenny didn’t have anything small enough to measure. But Autumn and Full sure did. Armed with Kenny’s micro-device, Full and Autumn wired up a gecko hair and loaded it with weight until it gave out. “We found out the forces were enormous,” says Full. “A patch about the size of a quarter could hold the weight of a small child. It was just unbelievable.” Even more inexplicable was the release mechanism. For gecko toes to work, they must not only adhere with tenacity, but also let go with ease. In earlier stages of research, Full and Autumn built large treadmills with clear plastic belts that allowed them to watch geckos’ feet as they ran. Using high-speed video equipment, they recorded something that other biologists had observed decades ago: toe peeling. In the few milliseconds it takes for a gecko to pick up its foot, its toes actually bend backwards and come off the ground before the heel does — sort of like rolling back like a piece of Scotch tape. So the researchers took their single hair and wrenched it back with just the same orientation that toe-peeling would provide. And off it came. “When you get to a critical angle of 30 degrees, [the hair] just pops off,” says Full. “Just like the toe peeling. We figured out the link between the toe movement and what’s going on at the hair level.” But the real mystery remained: the underlying force responsible for the gecko’s amazing sticking power. In a series of experiments, the team tested every possibility. First they counted out friction, because it was too weak. And then electrostatic forces, like static cling, because the charge of the surface made no difference to the adhesion. And then the interlocking hypothesis, like Velcro, because the geckos could still cling to exceptionally smooth surfaces. And then suction — used by many ocean creatures like octopuses or anemones — again because it’s too weak, but mostly because when they placed a gecko’s foot in a vacuum, it still stuck. The hardest hypothesis to discount was the use of some kind of glue, or wet adhesion — the type used by insects. But the scientists ruled that out, too when their detailed forensics couldn’t find a trace of glue anywhere. And geckos, unlike their glue-oozing colleagues, can stick underwater. It then came down to van der Waals forces, which they had suspected all along. The result was particularly exciting because van der Waals forces, named after the Dutch physicist who discovered them, depend solely on the intimacy of the contact between sticker and surface, not any special chemical properties of the material. In theory, says Full, synthetic gecko hairs can be made from any substance so long as they are fine enough to make the molecular contact. As a proof of principle, Full and Autumn asked Ron Fearing, the Berkeley engineer, to make some sample hairs. And they stuck.

IN HIS PRISTINE WHITE LAB, surrounded by a myriad of colorful wires, shining metal utensils and a host of computer screens, Fearing slips a tiny sliver of dried gecko foot under a regular microscope. To the naked eye it looks like an average toenail clipping, but then the hairs appear on a computer screen installed flush into a high cabinet. They stick out sideways, like a translucent profile of a carpet. The flower-like spatulae tips aren’t even visible with this weak magnification. A square centimeter of real gecko spatulae can hold about 2 pounds or 10 Newtons of weight. Fearing’s synthetic material can hold about half a Newton. Side by side comparisons of photos taken with an electron microscope reveal an almost indistinguishable similarity between one of Fearing’s fakes and a specimen of the simplest gecko foot, in which the toe hairs aren’t branched. Both look like a single plane of long, simple spatulae-width hairs all waving around like nanoscale wheat. He removes the foot slice and returns it to a drawer. In the next drawer below, he stores the molds he uses to make arrays of gecko-like hairs out of a variety of materials, including silicon rubber, polyester, epoxy and polyurethane. Fearing says his early work, crafting a few hairs with an individual strength comparable to that of a single gecko hair, was easy. Making the bigger dime-sized arrays of millions of hairs is more difficult. “Getting all those hairs to stick is the real challenge. Without having a gecko toe-pad, it’s hard,” said Fearing. It’s a common kind of problem in the biologically inspired design industry: Scientists often know what materials to use — Fearing can use almost anything — but getting down the building process is hard. For example, many groups of materials scientists are working on making synthetic bone implants from natural building blocks: a simple mineral called calcium carbonate and the tough protein collagen. Both materials are commercially available in any number of ways, including pastes, gels, and powders varying from fine to microsize. The main challenge is to somehow weave these two components together with the same intricate honeycomb structure that lends bone its strength and flexibility. A living, breathing bone cell can easily accomplish the task, but it’s not so simple for engineers. The same kind of issue is holding back the race to make synthetic spider silk, one of nature’s toughest materials, stronger per weight than high-tensile steel. Although researchers have isolated the proteins for spider silk, and even the underlying gene sequences, they’ve yet to find a way to recreate high-concentration liquid silk and the subsequent spinning process that makes the material so strong. In the case of gecko adhesives, another design problem to overcome is the hairs’ predisposition to stick together. Andre Geim, a physicist at the University of Manchester, also dabbled in creating gecko-like hairs after reading Autumn and Full’s research papers. Geim’s hairs clumped too. Because of that, after his team’s results were published last summer, they quit. “The arrays stick not only to themselves, they stick to the base surface,” Geim says. Fearing’s current engineering models suggest that by using a material that is really hard and repels water — just like the keratin in real gecko hairs — the clumping can be drastically reduced. Geim thinks that the gecko’s own design might be the key to success. “It’s not a big secret what the adhesive will require: hierarchical structures,” he says. “Not just a single layer of simple hairs.” Fearing agrees. The hierarchical complexity, he says, will not only decrease bunching, it will allow the adhesives to stick to something a little more impressive than just glass, the only surface that his group has experimented with so far. Real geckos can attach to rough surfaces because their toe-pads wrap and bend, allowing the maximal number of spatulae hairs to wheedle into tiny cracks and crevices and make the necessary intimate contact. Geim found that a flexible backing was an important aspect of his polymer arrays, likely because it allowed them to bend just like toe-pads. Fearing is coolly confident that it will be easy to make branched hairs once the basic geometry of the spatulae is clear. “The nanometer details that we’re starting out with are the hard part. Attaching the setal hairs, well, that’s just microtechnology,” he says. But at this point, he’s not even convinced that higher levels of complexity are necessary. “A very small wall-climbing robot does not need to be as good as the gecko. Geckos are maybe about a hundred times overdesigned to climb walls; if you took 1 percent of their hairs, it would still hold the full weight of the animal. We could easily build a really complicated adhesive structure — just make a more complicated mold. But what if there is a simple structure that works just as well? We don’t want to copy nature exactly, because we might be copying unnecessary complexity.” Other than clumping, Full and his partners must also address another facet of making successful synthetic gecko adhesives: cleanliness. Somehow, geckos manage to remove the tiny bits of dust and dirt from their own feet — particles that would otherwise completely destroy grasping ability — mere moments after they pick them up. “It’s a step that has to happen before gecko adhesives can go to commercial production,” says Geim. “At the moment, researchers have only promised it and these promises are only based on the knowledge that geckos can do it.” But for Full, Fearing and Autumn, knowing that the lizards can self-clean is reason enough to keep on pushing — after all, it's the same reason why they got into this sticky business to begin with. Autumn is now testing some hypotheses about how self-cleaning works. “That’s how you really make the big leaps, by looking at the principles,” says Full. It’s still another big leap to the realization of Full’s dreams. He imagines gecko adhesives holding together steel girders or covering the treads of robots bound for Mars and Jupiter’s moons. Or used as sutures in the operating room, or to enhance the gripping surfaces of rock-climbing shoes and baseball gloves. And while the sparkle in his eyes barely contains his excitement, he is careful to point out that he didn’t plan any of this. If anything, it all happened by accident. “We had fundamental basic curiosity that a five-year-old has, wondering how things work. And we worked hard to study gecko locomotion and understand the basic principles. We never knew where this would lead.”

For Full, the gecko story is like the fairytale of basic science

with a bigger moral: “If you have the application already in

mind, that’s all you’re going to get,” he says.

“We were just talking about how animals run around. It just

shows how critical it is to fund projects that sound wacky and

absurd to begin with.” |